Train passengers in the South East could soon be thanking Bristol intelligent video specialist One Big Circle for fewer delays after Network Rail contracted the firm to use its pioneering tech to detect critical faults on its lines.

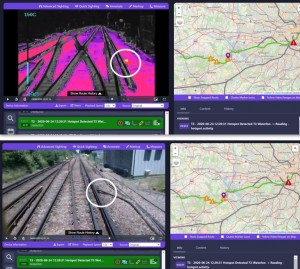

One Big Circle is to deploy its award-winning AIVR (Automated Intelligent Video Review) on-train technology fitted with thermal cameras to detect hot spots of over 80 degrees on the conductor – or third – rail.

It will be used in the South East – where much of the network is electrified and uses conductor rails – for the next six months.

The contract win follows intensive collaboration work between One Big Circle, which is based in Bristol’s Engine Shed tech hub, Network Rail’s Signalling Innovation Group (SIG) and its Intelligent Infrastructure group, which carried out a ‘proof of concept’ trial on the system last summer.

When One Big Circle’s existing AIVR software, which was built to detect anomalies in the rail infrastructure, is combined with the thermal camera it automatically detects and sends alerts detailing when and where the maximum temperature has been breached.

It can discover hot spots on both the conductor rail and connecting electrical cables, immediately sending the data back to the remote monitoring system and its team of engineers to verify.

During the trial period, which was supported by the region’s train operators such as Govia Thameslink Railway, more than 100 hours of video footage were captured and a range of examples of temperature breaches were detected by the technology.

Following the trial, the system could be rolled out across the entire UK rail network.

One Big Circle director and co-founder Emily Kent, pictured, said: “We are so pleased that our partnership with Network Rail has resulted in an ongoing solution that not only creates a more efficient reaction to safety critical scenarios, but also reduces the need for site inspections as we continue to operate within the confines of Covid-19 and beyond.

“Our technology provides engineers accurate data to instantly and remotely monitor situations online, ensuring they deploy the most appropriate team to deal with a fault quickly and effectively before it becomes a full failure of the line.

“This next stage of the project is really exciting and the collaborative relationship with Network Rail allows us to work right alongside those who will benefit directly from the technology and ensure it’s truly fit for purpose.”

Signalling Innovations Group innovations engineering manager David Shipman added: “Working with small and medium-sized enterprises such as One Big Circle enables us to bring specialist skills and innovative ideas into the industry to help us meet our challenges.

“The development of the thermal monitoring is just such an example and will help us improve safety and efficiency.”

Nearly half of the UK rail network is now electrified – and more than 30% of it uses a third rail to power the train.

Network Rail is increasingly using remote condition monitoring to detect faults on points, track circuits, signal power supplies and other parts of the network.

In the past year delays amounting to 153,000 minutes have been avoided, saving around £4.66m.

Transport for Wales (TfW) recently used One Big Circle’s AIVR devices on trains to automatically record, analyse and report vegetation risks along tracks.

One Big Circle is also taking part in global accountancy group PwC’s prestigious national Scale Transport Programme, which links tech scale-ups with the UK’s largest transport firms.