GKN Aerospace has received a second award for the wing section it makes for Airbus’s A350 XWB aircraft at its pioneering Severnside plant near Bristol.

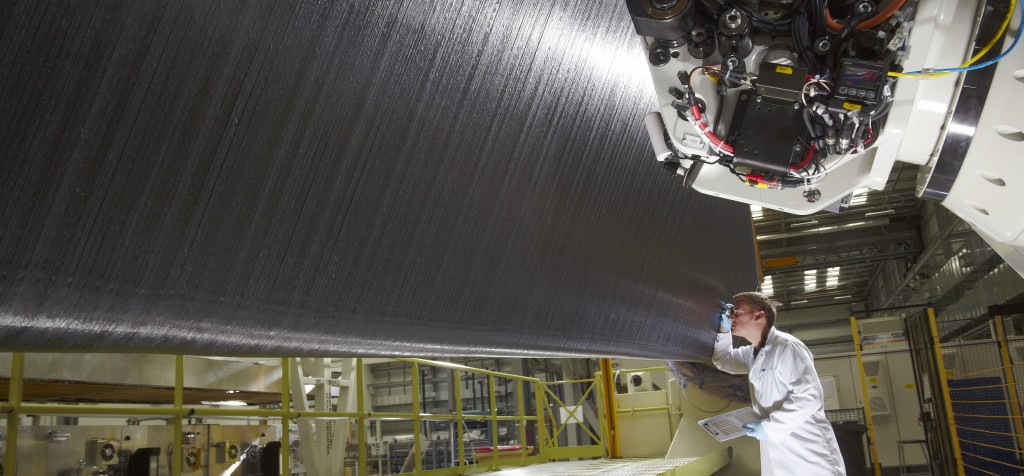

The 27m-long rear wing spar is manufactured in three sections using innovative, light-weight composite material and forms the structural heart of the A350 wing’s fixed trailing edge, holding vital parts such as the main landing gear.

GKN’s advanced manufacturing process and use of trailblazing materials earned it the prestigious Horners Award early last month in recognition of its pioneering design innovation in the use of plastics.

Now it has also landed the UK Composites Industry award for Innovation in Composites Design – one of eight awards made by Composite UK, the trade body for the UK composites industry.

The award was sponsored by the National Composites Centre (NCC), based at the Bristol & Bath Science Park, and rewards the significant manufacturing and materials progress achieved in developing this all-composite structure.

Both awards recognise the success of the intensive development and production programme for the A350 XWB wing spar, with GKN Aerospace engineers working closely with the Airbus engineering team at Filton and with US materials supplier Hexcel. As a result the spar has met demanding weight, strength and flexibility targets.

The spar has complex integral contours that enable it to carry heavy loads at critical points and yet remain flexible and lightweight.

GKN Aerospace chief engineering vice president Chris Gear said: “Creating the advanced manufacturing processes and materials to manufacture this innovative structure has strengthened the UK’s industrial lead in complex composite structure manufacture.

“Our partnership with Hexcel on this activity has been particularly rewarding and we believe the new material has immense potential.”

GKN Aerospace’s Severnside plant has been specially designed to produce this complex spar structure. The firm has created a totally new, advanced, automated manufacturing and assembly facility where it has introduced innovations across product design, manufacture and assembly, including, tooling and forming, finishing, assembly and testing.

Airbus has firm orders for 764 A350 XWBs (extra-wide body). As well as innovative composite wing parts, the twin-engine aircraft, which is yet to enter commercial service, also has all-new carbon fibre reinforced plastic fuselage resulting in lower fuel consumption, as well as easier maintenance. The three versions of the aircraft will seat between 250 and 400-plus passengers.

Pictured below: A composite wing spar section is inspected at GKN Aerospace’s state-of-the-art Severnside facility